Composite panels or insulated metal panels are among the most technologically advanced prefabricated elements for roof and wall cladding. The composite panels protect against the weather and serve as thermal insulation and vapor brake.

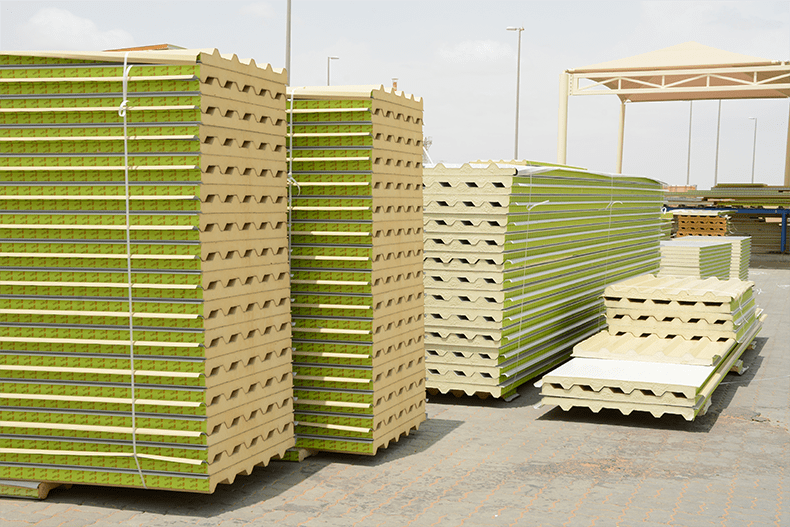

Packaging and Transport

Manufacturers stack insulated metal panels on polystyrene blocks or PU block for delivery. They are reinforced at the top and bottom with edge protection to protect the panels during loading, transportation, and unloading with lifting straps. Strapping must always be carefully checked and re-tensioned during transportation to avoid strapping marks. Do not exceed the packaged weight of max. 1500 kg. Larger packaging units available only under request.

Delivery

The driver is largely co-responsible for loading the truck and proper transportation. Please check immediately whether the panels have arrived undamaged. Check for completeness and any damage.

Immediately upon receipt, record any complaints on the transport documentation, including the license plate number and the driver’s name and including a photo of the relevant goods. Unfortunately, we cannot recognize complaints submitted at a later date.

Unloading

Use only slings for unloading. Use the slings only with edge protection. For panels longer than 8 m, use a crane jib or a spreader. Never unload two-panel stacks at the same time! Be cautious when using a forklift for unloading. The driver must monitor the unloading procedure carefully. He is responsible for proper hand-over.

Storage

Panels should not be stacked higher than two units. Cover the stacks with a canvas to protect insulated metal panels against sunlight and rain. Cover opened panel stacks. Position the panel stacks at a slight incline to allow water to run off.

Protective Film

The protective film is not UV resistant; please, therefore, remove the film immediately after installation or no later than ten weeks after the production date.