C purlin and Z purlin is a part of secondary framing structure. They are designed to distribute loads from the surface of your metal building to its primary framing and foundation. This adds longitudinal support and provides lateral bracing for compression flanges, increasing over all frame capacity.

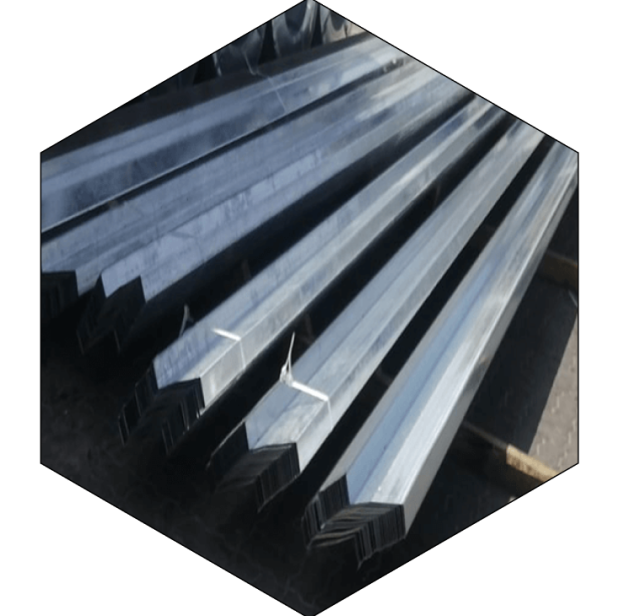

Steel purlins:

Steel purlins are a substitute for conventional wood purlins. They are lightweight, stable in dimension, accurate, and simple. They expand and contract moderately in extreme temperature changes. Typically, cold-formed material that is thin enough to pass through the screws is used to make steel purlins. Thin steel sheets are rolled or pressed into cold-formed steel to give it the necessary shape. To the producer, it is less costly than hot-rolled steel and, therefore, simpler to deal with. Although under stress cold-formed steel is more durable than hot-formed steel, it is more likely to crack than to bend.

EMI offers in locking C and Z designed to add aesthetic appeal and structural integrity to your building project.

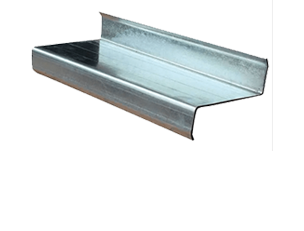

- Available in thicknesses ranging from 1.2 mm to 3.2 mm.

- Choose from EMI standard punching pattern.

- Material G 90 coated galvanized finish or as per customer requirement

- Various sizes.

Purlins are made of different metals. Some are plain mild steel with normal strength, while others have zinc coatings of varying GSM. In harsh weather, a special coating can be applied over and above the zinc coating.

- Dimension and shapes according to the Standard BS EN 1090-4:2018

- Material thickness according to EN 10143

The Z section is excellently suited as a roof purlin. The major principal inertia axis is in pitched roofs with normal inclination in an approximately vertical position and thereby provides optimum load bearing capacity against the weight of structures and snow. The second moment of area about the minor axis, on the other hand, is so low that it is usually advisable to tie the sheet section on the slope of the roof to the opposite slope by a ridge mounting. The Z section is installed on the roof with the upper flange pointing toward the ridge. Z sections are applicable also as wall purlins, installed with the outer flange facing down.

C sections can be used as wall purlins or wall posts. The C section differs from the Z section by its center of torsion, which in the C section is on the back side. Due to torsion, a vertical load acting on the section causes a transverse force component on the flange of the section, acting from the web up toward the upper flange. If C sections are used as roof purlins, they need to be installed with the upper flange pointing toward the ridge. As wall purlins, on the other hand, they are installed with the flange facing up, whereby wind pressure loads partly counteract the self-weight of the wall structure. With wind suction loads, the transverse force components strengthen one another, and tie rods may be required to counteract their influence.