- Thermal insulation with lowest thermal conductivity

- High compression strength with lower thickness and less weight

- Fire proof

- Lower costing

- Easy handing.

- Sound proof

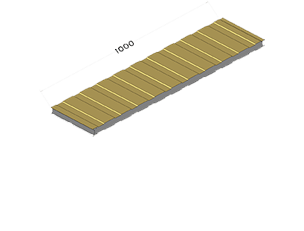

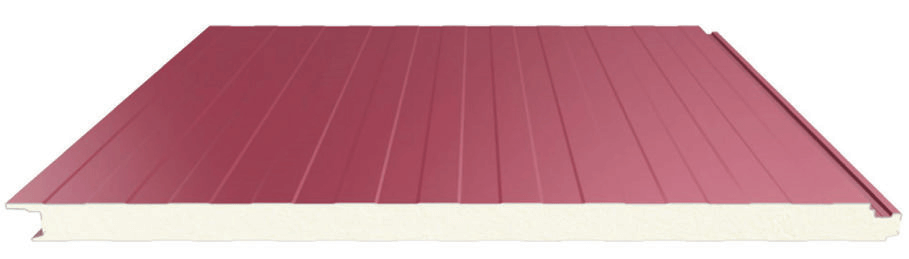

PU and PIR Sandwich panel

- The modern composite based building construction material, composed of insulated core and two metal facings.

- The wide range of application as roofs, walls and extended ceiling panels, partition wall in an easy building technology.

- There is a special range of flashing and other accessories, which cover opened cores and improve the final look of the building.

- The panels are available in different colors, sizes and thicknesses.

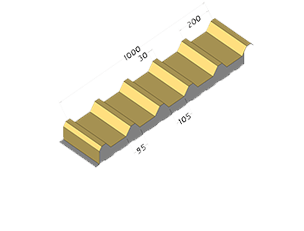

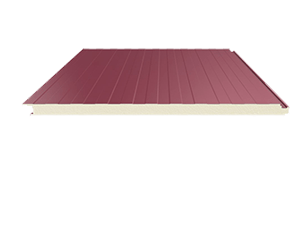

- EMI 35/200 (Roof & Wall)

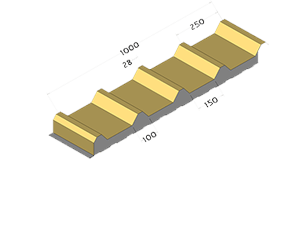

- EMI 45/250 (Roof & Wall)

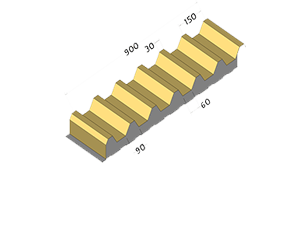

- EMI 45/150 (Roof & Wall)

- EMI TP 42/200 (Roof tile panel)

- Tongue and groove wall panel

- Slip joint panel (Cold store)

- Concealed fastener wall panel

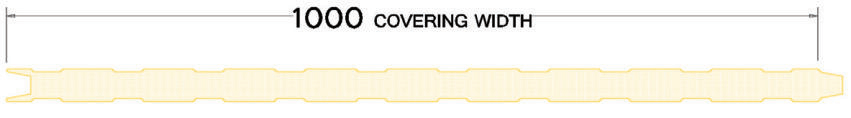

Tongue and groove wall panel

The “All in One” in plant partition wall system. The tongue and groove wall panel systems are ideal for creating in plant demising walls partitions quickly and cost effectively due to the minimal waste and shorter installation time frame compared to traditional construction materials. Plus, their modular design allows these wall systems to be moved or relocated a perfect solution that adapts with changing business needs. Reaching heights from floor to ceiling to completely enclose an area to create temperature and humidity controlled enclosures.

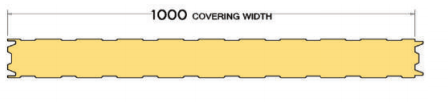

Slip Joint Panel (Cold Store)

Slip joint wall panel assembly especially used for cold room application. The double tongue and groove uses more surface area contact to reduce the possibility of thermal leakage, hence resulting in improved thermal resistance.

Wall panel – concealed fastener type

- Superior aesthetic appearance

- Form a smooth facade with no visible joints

- Maintains good insulation properties

- Can be tied vertically and horizontally

Sandwich panel concealed fixing method for high quality industrial and commercial buildings. Where good aesthetics are paramount. The panel external micro ribs increase the aesthetic appeal of this panel. Which can be oriented both vertically and horizontally as required.

The color of the external facing influences the self-heating temperature of the panel surface, when exposed to sun rays, which can result in thermal expansion properties, which, in turn, affect the strength of both the panel and the facing. There are three groups of sandwich panel facing colors: Group I – very bright colors, Group II – bright colors, Group III – dark colors

COLOR TABLE FOR SANDWICH PANEL FACINGS

| Color group / surface self-heating in the summer | Color number as per the RAL system | Reflectance coefficient for the RG facing [%] |

| I – very bright colors, temperature up to 55°C | 1015, 1018, 7035, 9001, 9002, 9010 | 75-90 |

| II – bright colors, temperature up to 65°C | 1002, 1007, 1021, 2008, 5012, 6011, 6018, 9006, 7040 | 40-74 |

| III – dark colors, temperature up to 80°C | 3000, 3005, 3011, 3016, 5010, 5011, 6003, 6005, 6011, 6029, 7016, 7024, 8017, 9007 | 8-39 |